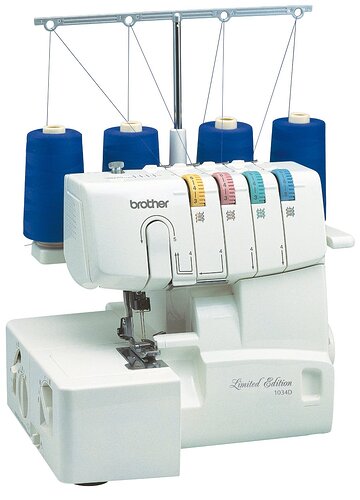

I own the Brother 1034D Overlocker (Serger) - it’s been a very popular model of entry-level machine worldwide for maybe 15+ years.

Mine is 13 years old, still going strong and I’ve never had it professionally cleaned or serviced.

I’ve changed one of the cutting blades myself (thank you YouTube for the handy how-to video ![]() + eBay for the inexpensive generic-compatible replacement blade).

+ eBay for the inexpensive generic-compatible replacement blade).

And, I’ve unscrewed the entire plastic case + bottom base + cleaned + oiled all the moving metal parts myself. It wasn’t hard to do. (NOTE: That the instruction manual book ![]() only has you oil a couple of parts and definitely does not tell you to unscrew the case like I did

only has you oil a couple of parts and definitely does not tell you to unscrew the case like I did ![]() .)

.)

I’ve a YouTube playlist of videos saved here ![]()

![]() Sewing - Oil Overlocker, Brother 1034D that helped me.

Sewing - Oil Overlocker, Brother 1034D that helped me.

My top tips when unscrewing everything ![]()

![]()

![]() …

…

![]()

![]()

![]() Take photos of the parts that you unscrew as you go to remember where to put them back afterwards (I even use a pencil

Take photos of the parts that you unscrew as you go to remember where to put them back afterwards (I even use a pencil ![]() to point to them in my

to point to them in my ![]() ).

).

![]() Get a bunch of little bowls

Get a bunch of little bowls ![]() (or lids from jars work too) to keep the

(or lids from jars work too) to keep the ![]()

![]() nuts & screws in and if it helps you also label the bowls with scraps of

nuts & screws in and if it helps you also label the bowls with scraps of ![]() or a post-it-note too.

or a post-it-note too.

![]() Vacuum + wipe away dust/debris first, then oil with only the teensiest drop

Vacuum + wipe away dust/debris first, then oil with only the teensiest drop ![]() of sewing machine oil (NEVER WD40!) on all metal-on-metal moving parts.

of sewing machine oil (NEVER WD40!) on all metal-on-metal moving parts.

[I originally posted this as a reply to another forum member’s comment. But, I felt it was worthwhile sharing it in it’s own right as it’s very useful ![]() .]

.]